-

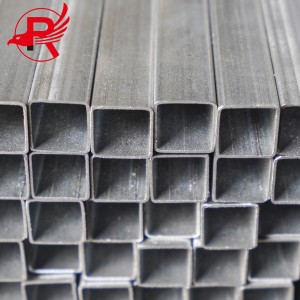

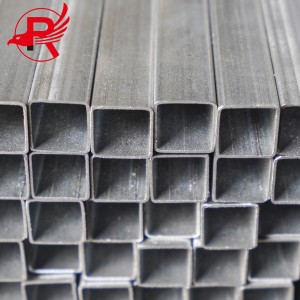

Заводські найкращі якісні гарячі продажі гарячеоцинкованих квадратних прямокутних сталевих труб

Гаряче оцинкована трубаГаряче цинкування – це реакція розплавленого металу із залізною матрицею для утворення шару сплаву, в результаті чого матриця та покриття об'єднуються. Гаряче цинкування полягає в попередньому травленні сталевої труби для видалення оксиду заліза з її поверхні. Після травлення поверхня труби проходить через водний розчин хлориду амонію або хлориду цинку, або водний розчин хлориду амонію та хлориду цинку, а потім подається в резервуар для гарячого цинкування. Гаряче цинкування має такі переваги, як рівномірне покриття, міцна адгезія та тривалий термін служби. Матриця гарячеоцинкованої сталевої труби та розплавлена ванна проходять складні фізичні та хімічні реакції, утворюючи щільний шар сплаву цинку та заліза, стійкий до корозії. Шар сплаву інтегрований із шаром чистого цинку та матрицею сталевої труби, тому він має високу корозійну стійкість.

-

Оцинковані порожнисті труби калібру 14, залізні квадратні сталеві труби заводу 2×2

Оцинкована квадратна труба- це різновид порожнистої сталевої труби квадратного перерізу з квадратною формою та розміром, виготовленої з гарячекатаної або холоднокатаної оцинкованої стрічкової сталі або оцинкованої котушки у вигляді заготовки шляхом холодного гнуття, а потім за допомогою високочастотного зварювання, або холодноформованої порожнистої сталевої труби, виготовленої заздалегідь, а потім за допомогою гарячеоцинкованої квадратної труби.

-

Гарячеоцинкована кругла сталева труба SAE 1008 1010 1020

Gальванізована трубавиготовляється з реакції розплавленого металу та залізної матриці для отримання шару сплаву, таким чином, матриця та покриття є двома комбінаціями.gАльванізація полягає в попередньому травленні сталевої труби. Для видалення оксиду заліза з поверхні сталевої труби після травлення її очищують у резервуарі з розчином хлориду амонію або хлориду цинку, або змішаним водним розчином хлориду амонію та хлориду цинку, а потім відправляють у резервуар для гарячого цинкування. Гаряче цинкування має такі переваги, як рівномірне покриття, міцна адгезія та тривалий термін служби. Між основою сталевої труби та розплавленою ванною відбуваються складні фізичні та хімічні реакції, утворюючи компактний шар сплаву цинку та заліза, стійкий до корозії. Шар сплаву інтегрований з шаром чистого цинку та матрицею сталевої труби. Тому він має високу корозійну стійкість.

Маючи понад 10 років досвіду експорту сталі до понад 100 країн, ми здобули чудову репутацію та безліч постійних клієнтів.

Ми надамо вам повну підтримку протягом усього процесу, використовуючи наші професійні знання та високоякісні товари.

Зразок на складі безкоштовний та доступний! Ласкаво просимо до вашого запиту!

-

Високоякісна гарячеоцинкована кругла сталева труба діаметром 15 мм

Gальванізована трубавиготовляється з реакції розплавленого металу та залізної матриці для отримання шару сплаву, таким чином, матриця та покриття є двома комбінаціями.gАльванізація полягає в попередньому травленні сталевої труби. Для видалення оксиду заліза з поверхні сталевої труби після травлення її очищують у резервуарі з розчином хлориду амонію або хлориду цинку, або змішаним водним розчином хлориду амонію та хлориду цинку, а потім відправляють у резервуар для гарячого цинкування. Гаряче цинкування має такі переваги, як рівномірне покриття, міцна адгезія та тривалий термін служби. Між основою сталевої труби та розплавленою ванною відбуваються складні фізичні та хімічні реакції, утворюючи компактний шар сплаву цинку та заліза, стійкий до корозії. Шар сплаву інтегрований з шаром чистого цинку та матрицею сталевої труби. Тому він має високу корозійну стійкість.

-

Труба GI Попередньо оцинкована сталева труба Оцинкована труба для будівництва

ЗварюванняОцинкована трубазазвичай виготовляється з низьковуглецевої сталі та широко використовується в різних сферах застосування, таких як будівництво, інфраструктура, промислові та житлові проекти. Процес цинкування забезпечує сталевій трубі додаткову міцність та довговічність, що робить її придатною для використання на відкритому повітрі та в умовах підвищеної чутливості.

Головна перевагапопередньо оцинкована сталева труба– це його стійкість до корозії. Цинкове покриття діє як бар'єр, який запобігає контакту вологи та інших агресивних речовин з нижньою сталлю. Це робить попередньо оцинковану сталеву трубу менш схильною до іржі та корозії, збільшуючи термін її служби та зменшуючи витрати на обслуговування.

Крім того,Гаряче оцинкована трубавідомий своєю високою міцністю та жорсткістю. Він може витримувати великі навантаження та забезпечує чудову структурну цілісність, що робить його надійним вибором для застосувань, які потребують міцної та стійкої труби.

-

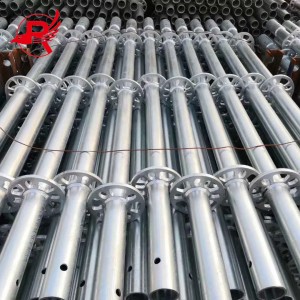

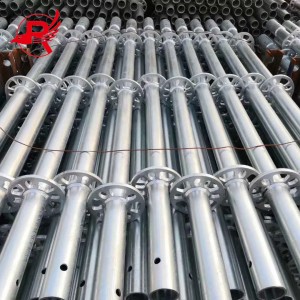

Труби та труби з вуглецевої сталі з цинковим покриттям, труби для риштувань, гарячеоцинковані сталеві труби

СтальриштуванняКронштейн — це тимчасова конструкція, яка забезпечує стабільну платформу для робітників для виконання будівельних, ремонтних або технічних робіт на висоті. Він складається зі сталевих труб та фітингів, з'єднаних разом, утворюючи стабільну раму. Сталеві опори риштувань можуть відрізнятися за розміром та конфігурацією залежно від типу робіт, які необхідно виконати, та необхідної висоти.

-

Повні металеві важкі риштування гарячеоцинковані всесторонні риштування Layher Ringlock System на продаж

СтальриштуванняКронштейн — це тимчасова конструкція, яка забезпечує стабільну платформу для робітників для виконання будівельних, ремонтних або технічних робіт на висоті. Він складається зі сталевих труб та фітингів, з'єднаних разом, утворюючи стабільну раму. Сталеві опори риштувань можуть відрізнятися за розміром та конфігурацією залежно від типу робіт, які необхідно виконати, та необхідної висоти.

-

Високоякісні сталеві риштування Ringlock для будівництва, що вживаються, на продаж

СтальриштуванняКронштейн — це тимчасова конструкція, яка забезпечує стабільну платформу для робітників для виконання будівельних, ремонтних або технічних робіт на висоті. Він складається зі сталевих труб та фітингів, з'єднаних разом, утворюючи стабільну раму. Сталеві опори риштувань можуть відрізнятися за розміром та конфігурацією залежно від типу робіт, які необхідно виконати, та необхідної висоти.

-

Труба для риштування з гарячеоцинкованого сталевого оцинкованого матеріалу

Gальванізована трубавиготовляється з реакції розплавленого металу та залізної матриці для отримання шару сплаву, таким чином, матриця та покриття є двома комбінаціями.gАльванізація полягає в попередньому травленні сталевої труби. Для видалення оксиду заліза з поверхні сталевої труби після травлення її очищують у резервуарі з розчином хлориду амонію або хлориду цинку, або змішаним водним розчином хлориду амонію та хлориду цинку, а потім відправляють у резервуар для гарячого цинкування. Гаряче цинкування має такі переваги, як рівномірне покриття, міцна адгезія та тривалий термін служби. Між основою сталевої труби та розплавленою ванною відбуваються складні фізичні та хімічні реакції, утворюючи компактний шар сплаву цинку та заліза, стійкий до корозії. Шар сплаву інтегрований з шаром чистого цинку та матрицею сталевої труби. Тому він має високу корозійну стійкість.

Маючи понад 10 років досвіду експорту сталі до понад 100 країн, ми здобули чудову репутацію та безліч постійних клієнтів.

Ми надамо вам повну підтримку протягом усього процесу, використовуючи наші професійні знання та високоякісні товари.

Зразок на складі безкоштовний та доступний! Ласкаво просимо до вашого запиту!

-

HDG Tube Китайський завод безпосередньо за ціною оцинкованих зварних круглих сталевих труб

Оцинкована кругла сталева труба– це тип круглої сталевої труби з поверхнею, обробленою гарячим або холодним цинкуванням, що забезпечує чудову стійкість до корозії та довговічність. Вона широко використовується в будівництві, машинобудуванні, сільськогосподарських об'єктах, трубопровідному транспорті, захисних огорожах та промислових спорудах.

-

EN10255 8-дюймові гарячекатані труби та трубки з оцинкованого м'якого вуглецевої сталі S235 з цинковим покриттям

Gальванізована трубавиготовляється з реакції розплавленого металу та залізної матриці для отримання шару сплаву, таким чином, матриця та покриття є двома комбінаціями.gАльванізація полягає в попередньому травленні сталевої труби. Для видалення оксиду заліза з поверхні сталевої труби після травлення її очищують у резервуарі з розчином хлориду амонію або хлориду цинку, або змішаним водним розчином хлориду амонію та хлориду цинку, а потім відправляють у резервуар для гарячого цинкування. Гаряче цинкування має такі переваги, як рівномірне покриття, міцна адгезія та тривалий термін служби. Між основою сталевої труби та розплавленою ванною відбуваються складні фізичні та хімічні реакції, утворюючи компактний шар сплаву цинку та заліза, стійкий до корозії. Шар сплаву інтегрований з шаром чистого цинку та матрицею сталевої труби. Тому він має високу корозійну стійкість.

-

Гаряче оцинкована зварена кругла труба з вуглецевої сталі Astm

Гаряче цинкування – це форма цинкування. Це процес покриття заліза та сталі цинком, який сплавляється з поверхнею основного металу при зануренні металу у ванну з розплавленим цинком за температури близько 450 °C (842 °F).

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur