Знижка за пряму ціну від заводу може бути налаштована на розмір оцинкованої труби

Зокрема, його використовують переважно в таких сферах:

1. Будівельна галузь: така як каркаси будівель, сталеві конструкції, огорожі сходів тощо;

2. Транспортна галузь: така як дорожні огорожі, суднові конструкції, автомобільні шасі тощо;

3. Металургійна галузь: така як трубопровідні системи для транспортування руди, вугілля, шлаку тощо.

Як сталевий трубний виріб із сильним технічним складом, оцинковані труби мають широкий спектр застосування та багато переваг. Вони є незамінним матеріалом для трубопровідних систем у будівництві, транспорті, металургії та інших галузях. У майбутньому ринковому попиті оцинковані труби матимуть ширші перспективи застосування.

Застосування

1. Антикорозійні властивості: Поверхня оцинкованої труби покрита шаром цинку, який має сильні антикорозійні властивості та не іржавіє після тривалого використання.

2. Довговічність: Завдяки оцинковуванню на поверхні, оцинковані труби мають високу міцність і відносно тривалий термін служби.

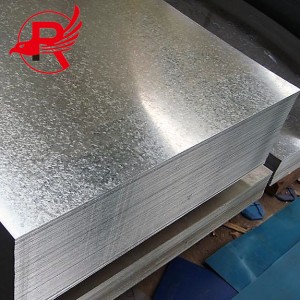

3. Естетика: Поверхня оцинкованої труби гладка та блискуча, її можна використовувати безпосередньо без обробки поверхні.

4. Пластичність: Оцинковані труби мають добру пластичність під час виробничого процесу, і за потреби можна виготовляти труби різної форми.

5. Зварюваність: Оцинковані труби легко зварюються під час виробничого процесу, що полегшує будівництво.

Параметри

| Назва продукту | Оцинкована труба |

| Оцінка | Q235B, SS400, ST37, SS41, A36 тощо |

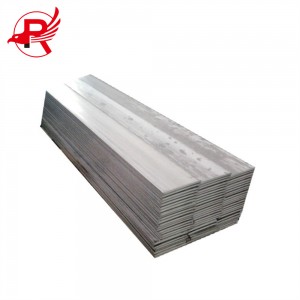

| Довжина | Стандартні 6 м та 12 м або за вимогою замовника |

| Ширина | 600 мм-1500 мм, відповідно до вимог замовника |

| Технічні | Гаряче оцинкованетруба |

| Цинкове покриття | 30-275 г/м2 |

| Застосування | Широко використовується в різних будівельних конструкціях, мостах, транспортних засобах, кріпленнях, машинах тощо. |

Деталі

Цинкові шари можуть виготовлятися від 30 г до 550 г і можуть постачатися з гарячим цинкуванням, електричним цинкуванням та попереднім цинкуванням. Забезпечує підтримку виробництва цинкового шару після звіту про перевірку. Товщина виготовляється відповідно до контракту. Наша компанія обробляє з допуском товщини в межах ±0,01 мм. Цинкові шари можуть виготовлятися від 30 г до 550 г і можуть постачатися з гарячим цинкуванням, електричним цинкуванням та цинкуванням. Забезпечує підтримку виробництва цинкового шару після звіту про перевірку. Товщина виготовляється відповідно до контракту. Наша компанія обробляє з допуском товщини в межах ±0,01 мм. Лазерне різання сопла, сопло гладке та акуратне. Труба з прямим швом, оцинкована поверхня. Довжина різання від 6 до 12 метрів, ми можемо забезпечити американський стандарт довжини 20 футів 40 футів. Або ми можемо відкрити форму для налаштування довжини виробу, наприклад, 13 метрів тощо. Склад 50 000 м². Виробляється понад 5000 тонн. товарів на день, тому ми можемо забезпечити їм найшвидший час доставки та конкурентоспроможну ціну.

Оцинкована труба є поширеним будівельним матеріалом і використовується в широкому діапазоні. Під час транспортування, через вплив факторів навколишнього середовища, легко виникнути такі проблеми, як іржа, деформація або пошкодження сталевої труби, тому це дуже важливо для пакування та транспортування оцинкованих труб. У цій статті буде представлено метод пакування оцинкованих труб під час транспортування.

2. Вимоги до упаковки

1. Поверхня сталевої труби повинна бути чистою та сухою, без жиру, пилу та іншого сміття.

2. Сталева труба повинна бути упакована двошаровим папером з пластиковим покриттям, зовнішній шар покритий пластиковим листом товщиною не менше 0,5 мм, а внутрішній шар покритий прозорою поліетиленовою плівкою товщиною не менше 0,02 мм.

3. Сталева труба повинна бути маркована після упаковки, і маркування повинно містити тип, специфікацію, номер партії та дату виробництва сталевої труби.

4. Сталеві труби слід класифікувати та упаковувати відповідно до різних категорій, таких як специфікація, розмір та довжина, щоб полегшити завантаження, розвантаження та складування.

По-третє, спосіб упаковки

1. Перед пакуванням оцинкованої труби поверхню труби слід очистити та обробити, щоб переконатися, що вона чиста та суха, щоб уникнути таких проблем, як корозія сталевої труби під час транспортування.

2. Під час пакування оцинкованих труб слід звернути увагу на захист сталевих труб та використовувати червоні коркові шини для зміцнення обох кінців сталевих труб, щоб запобігти деформації та пошкодженню під час пакування та транспортування.

3. Пакувальний матеріал оцинкованої труби повинен мати вологостійкі, водонепроникні та іржостійкі властивості, щоб забезпечити захист сталевої труби від вологи чи іржі під час транспортування.

4. Після упаковки оцинкованої труби зверніть увагу на вологостійкість та сонцезахисний крем, щоб уникнути тривалого впливу сонячного світла або вологого середовища.

4. Запобіжні заходи

1. При упаковці оцинкованих труб необхідно враховувати стандартизацію розміру та довжини, щоб уникнути відходів та втрат, спричинених невідповідністю розмірів.

2. Після пакування оцинкованої труби необхідно вчасно її маркувати та класифікувати, щоб полегшити управління та складування.

3, при упаковці оцинкованої труби слід звернути увагу на висоту та стійкість штабелювання товарів, щоб уникнути нахилу товарів або занадто високого штабелювання, що може призвести до пошкодження товарів.

Вищезазначений метод пакування оцинкованих труб у процесі транспортування, включаючи вимоги до пакування, методи пакування та запобіжні заходи. Під час пакування та транспортування необхідно суворо дотримуватися правил та ефективно захищати сталеві труби, щоб забезпечити безпечне прибуття товару до місця призначення.

1. Які ваші ціни?

Наші ціни можуть змінюватися залежно від пропозиції та інших ринкових факторів. Ми надішлемо вам оновлений прайс-лист після того, як ваша компанія зв'яжеться з нами.

до нас для отримання додаткової інформації.

2. Чи є у вас мінімальна кількість замовлення?

Так, ми вимагаємо, щоб усі міжнародні замовлення мали постійну мінімальну кількість замовлення. Якщо ви хочете перепродавати, але в значно менших кількостях, радимо вам відвідати наш вебсайт.

3. Чи можете ви надати відповідну документацію?

Так, ми можемо надати більшість документів, включаючи сертифікати аналізу/відповідності; страхування; документи про походження та інші експортні документи, якщо це необхідно.

4. Який середній час виконання замовлення?

Для зразків термін виконання замовлення становить близько 7 днів. Для масового виробництва термін виконання замовлення становить 5-20 днів після отримання передоплати. Терміни виконання замовлення набувають чинності з моменту

(1) ми отримали ваш депозит, та (2) ми отримали ваше остаточне схвалення щодо вашої продукції. Якщо наші терміни виконання не відповідають вашому дедлайну, будь ласка, обговоріть ваші вимоги з вашим продажем. У будь-якому випадку ми спробуємо задовольнити ваші потреби. У більшості випадків нам це вдається.

5. Які способи оплати ви приймаєте?

30% авансом T/T, 70% буде перед відправкою на умовах FOB; 30% авансом T/T, 70% буде передплачено на основі копії BL на умовах CIF.